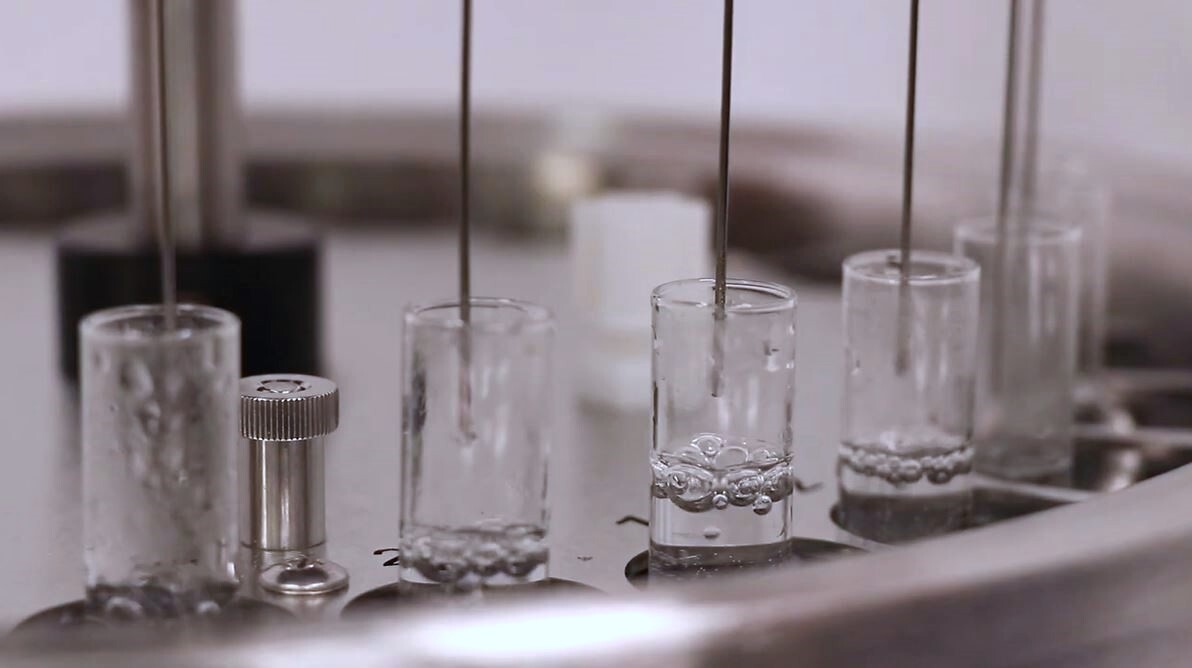

In sample preparation, evaporation efficiency directly influences throughput, solvent recovery, and overall lab productivity. One of the most critical factors affecting evaporation performance is bath temperature. It is commonly understood that heating a liquid will increase the rate of evaporation and this principle can be applied during sample preparation to decrease overall work time. When using the N-EVAP nitrogen evaporator, this is easily achievable with the addition of a heated water bath to the system.

The Role of Heat in Evaporation

Evaporation rate is driven by the vapor pressure of the solvent, which increases exponentially with temperature. Higher temperatures create an increase in the kinetic energy of liquid molecules, which allows more of them to overcome their intermolecular forces and escape into the gas phase, therefore evaporating.

When applied temperature increases:

- Solvent molecules gain more energy allowing faster escape into the gas phase.

- Evaporation rates accelerate, reducing total drying time.

- Nitrogen flow becomes more effective at removing vapors from the sample surface.

However, excessive heat can also lead to:

- Sample degradation, especially with heat-sensitive compounds.

- Potential loss of volatile analytes, impacting overall accuracy.

- Safety concerns with highly flammable solvents.

Real World Data

In order to gain a better understanding of individual solvent evaporation rates, experimental trials were conducted using the N-EVAP nitrogen evaporator at both room temperature and an elevated temperature, relative to the boiling point of the solvent. All trials were conducted using 19-gauge needles with a nitrogen flow rate of 0.33 LPM (liters per minute) per sample, as recommended by Organomation. Evaporation was observed to be approximately 3–9 times faster when a heated water bath was employed, although the extent of improvement varied among solvents. The table below demonstrates these results.

Table 1. Evaporation Rate of Common Solvents

|

Solvent |

Room Temperature Evaporation Rate (mL/hr) |

Heated Water Bath Evaporation Rate (mL/hr) |

|

Methanol |

3.5 mL |

At 63°C - 22 mL |

|

Hexane |

12 mL |

At 69°C - 54 mL |

|

Ethanol |

2.5 mL |

At 75°C - 18 mL |

|

Isopropanol |

2.3 mL |

At 75°C - 18 mL |

|

Ethyl Acetate |

5.75 mL |

At 70°C - 30 mL |

|

Acetone |

8.2 mL |

At 50°C - 36 mL |

|

Acetonitrile |

3.5 mL |

At 75°C - 23 mL |

|

Toluene |

2.1 mL |

At 80°C - 14 mL |

|

Methyl tert-butyl ether |

12 mL |

At 50°C - 48 mL |

|

Dichloromethane |

9.4 mL |

At 35°C - 27 mL |

|

Dimethylformamide |

0.3 mL |

At 90°C - 2.9 mL |

|

Chloroform |

7.4 mL |

At 58°C - 37 mL |

Additionally, the evaporation rates of various solvent mixtures were determined. Similarly, these trials were conducted at both room temperature and elevated temperature using the recommended needle and flow rate parameters. Evaporation rates were significantly higher under heated conditions, increasing 3–10 times compared to unheated samples. The table below highlights these results.

Table 2. Solvent Mixture Evaporation Rates

|

Solvent Mixture |

Room Temperature Evaporation Rate (mL/hr) |

Heated Water Bath Evaporation Rate (mL/hr) |

|

80:20 Acetonitrile: Deionized Water |

3.0 mL |

At 74°C - 31 mL |

|

1:1 Methanol: Deionized Water |

1.2 mL |

At 63°C - 8.6 mL |

|

1:1 Acetone: Dichloromethane |

7.3 mL |

At 37°C - 24 mL |

|

40:40:20 Acetonitrile: Methanol: Deionized Water |

3.4 mL |

At 61°C - 20 mL |

|

3:1 Acetone: Toluene |

8.7 mL |

At 56°C - 46 mL |

|

1:1 Methanol: Acetonitrile |

4.1 mL |

At 61°C - 31 mL |

|

1:1 Methanol: Ethyl Acetate |

5.7 mL |

At 60°C - 29 mL |

|

1:1 Methanol: Chloroform |

5.8 mL |

At 51°C - 38 mL |

What's the Right Temperature?

In order to optimize laboratory efficiency, it is critical to select the appropriate bath temperature for each sample and solvent. This parameter is a pivotal factor in the evaporation process, directly influencing the rate of solvent removal and overall sample preparation time.

How to Select Bath Temperature

1. Start Below the Solvent’s Boiling Point

- Operating near but below the boiling point (5–10 °C lower) ensures rapid evaporation without violent bubbling.

2. Match Applied Temperature to the Solvents Relative Volatility

- High-volatility solvents require lower bath temperatures.

- Medium-volatility solvents work best with moderate temperatures.

- Low-volatility solvents require higher temperatures for increased evaporation rates.

3. Sample Stability Considerations

- Some biological samples, pharmaceuticals, and other heat-sensitive compounds may require more gentle drying at lower temperatures or with decreased nitrogen flow to prevent degradation and aerosolization.

In cases where the sample type does not permit heating near the solvent’s boiling point, applying a gentle heating may be a more suitable alternative. For example, in additional trials, methanol and hexane were evaporated in a 40 °C water bath and both still demonstrated a significant increase in evaporation rate compared to evaporation at room temperature. Overall, heating methanol to 40 °C increased its evaporation rate by nearly 3 times, while hexane's rate increased by about 2.5 times. Notably, full heating resulted in approximately 6 times the unheated rate for methanol and 4.5 times the unheated rate for hexane. These results are displayed in Table 3 and further illustrated in Figures 1 and 2, which depict solvent evaporation across a range of temperatures.

Table 3. Methanol and Hexane Evaporation Series

|

Solvent |

Room Temperature Evaporation Rate (mL/hr) |

Evaporation Rate at 40℃ (mL/hr) |

Evaporation at Recommended Bath Temperature (mL/hr) |

|

Methanol |

3.5 mL |

9.6 mL |

At 63°C - 22 mL |

|

Hexane |

12 mL |

30 mL |

At 69°C - 54 mL |

Figure 1. Methanol evaporation at increasing temperatures

Figure 2. Hexane evaporation at increasing temperatures

Conclusion

Bath temperature is a primary driver of evaporation rates, and effective heating is essential for increasing laboratory productivity. However, balancing evaporation speed, laboratory safety, and sample quality are also important factors to consider. Implementing a water bath into your evaporation step can help address these considerations.

Advantages of a Water Bath

1. Uniform Heating: ensures consistent drying across multiple vials

2. Precise Temperature Control: optimizes evaporation without overheating samples

3. Gentle Nitrogen Flow: displaces solvent vapors efficiently while minimizing sample disturbance

It was demonstrated that increasing sample temperature using a water bath significantly enhances evaporation rates. Additionally, even a slight increase to 40 °C resulted in a significantly faster evaporation for solvents methanol and hexane, when compared to evaporation at room temperature. This temperature flexibility is valuable for heat-sensitive analytes, enabling full optimization of laboratory time without compromising sample integrity.

Throughout this process, the N-EVAP nitrogen evaporator performed exceptionally, offering precise control that allowed for fine-tuning across a wide range of solvents and applications. Its reliability and versatility make it an indispensable tool for efficient and reproducible sample preparation.

Determine how long it would take your samples to dry down in Organomation's N-EVAP evaporator: