Solvent evaporation is a critical step in sample preparation across a wide range of laboratory applications, from environmental analysis to pharmaceutical research. While commercial nitrogen blowdown evaporators are available for efficient and controlled solvent removal, many labs use homemade evaporation setups as an alternative. These setups range from Schlenk lines and open-air drying stations to custom manifold systems and fan-and-hotplate combinations.

While DIY solutions can work in a pinch, they often come with significant limitations in speed, reproducibility, gas efficiency, and cost-effectiveness. If your lab is evaporating more than a couple of samples at a time—or even as few as a handful of samples per week—it may be time to consider switching to a professional nitrogen blowdown system.

Common DIY Evaporation Setups

1. Schlenk Lines for Sample Evaporation

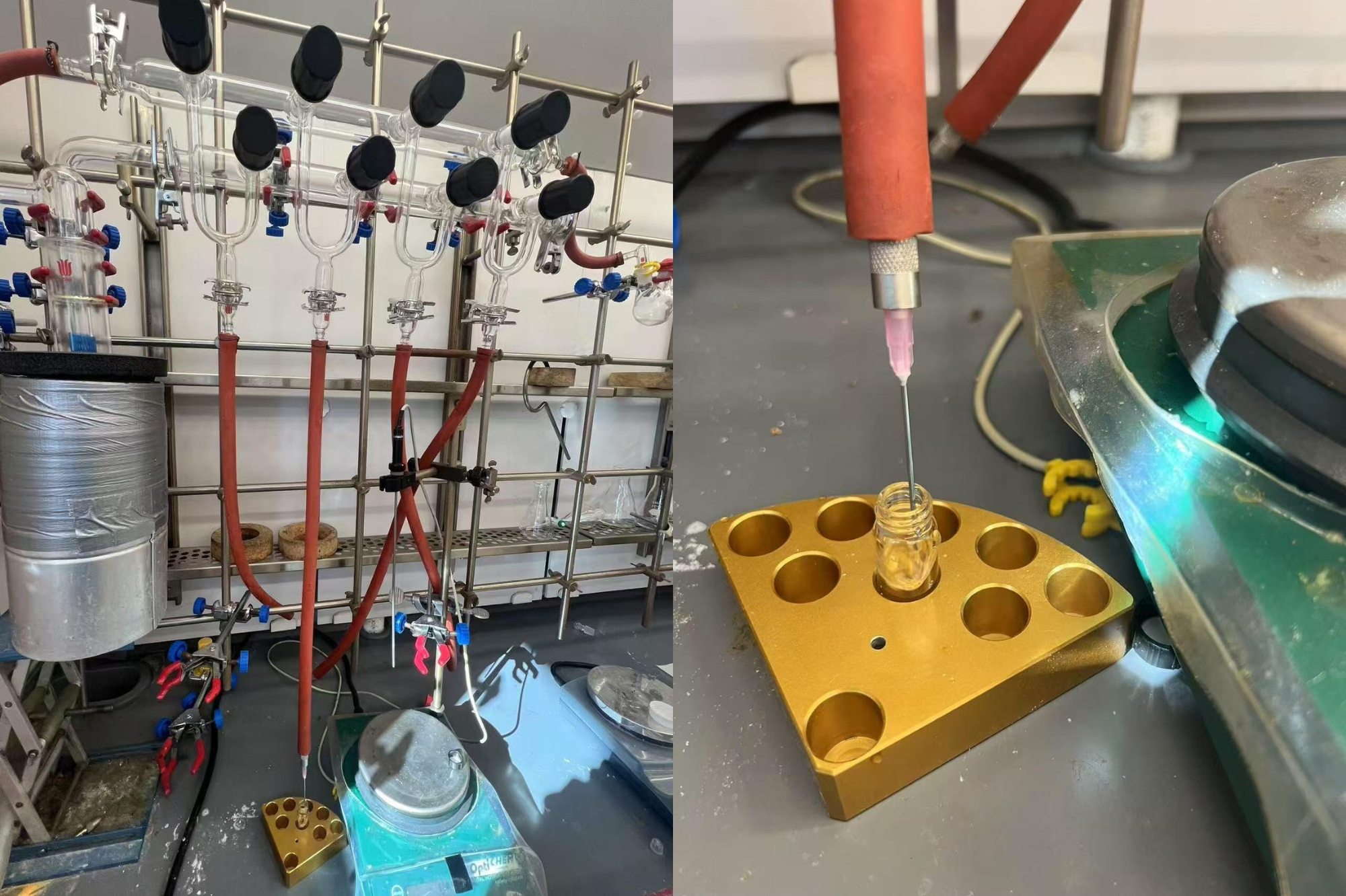

Schlenk lines are widely used in chemistry labs for handling air-sensitive reactions, but some researchers also use them for solvent evaporation. These systems allow for controlled nitrogen flow to help dry down samples. However, Schlenk lines are not optimized for evaporation efficiency, and they are generally limited to one or two samples at a time.

.jpg?width=289&height=386&name=Homemade%20Setup%205%20(pt%201).jpg)

Best for:

- Labs who already use Schlenk lines for other purposes and have them set up in their fume hood

- Labs working with a very small number of samples at a time

- Small, volatile samples that don't require heat to evaporate quickly

Limitations:

- Inefficient for batch processing: Not designed for handling more than a couple samples at a time

- No built-in heating elements which can extend drying times

- Lack of precise gas flow control to individual samples

2. Custom Manifold and Gas Flow Systems

Some labs create homemade nitrogen manifolds using custom-machined racks and needle assemblies. This can be a great low-cost option if the lab tech has access to a machine shop and is confident in their ability to create a fully functional setup with no gas leaks or other hinderances. If not, these custom setups are often ordered from specialty machine shops to accommodate specific tube or plate sizes. While they can be a practical and affordable solution, customization and setup fees can easily cost hundreds or even thousands of dollars—often approaching the price of a professional nitrogen evaporator.

Another major drawback of homemade manifold systems is gas leaks or uneven gas flow between sample positions. Poorly fitted tubing, low-quality connections, or imprecise valve control can lead to significant nitrogen loss, increasing operating costs and reducing efficiency.

Best for:

- Occasional sample evaporation that does not justify a full-scale system

- Labs who have access to machine shops or 3D printers who can cheaply manufacture this custom parts

Limitations:

- High upfront costs: Custom sample holders and gas manifolds often require expensive machining

- Potential gas leaks: Poorly sealed connections can waste large amounts of nitrogen

- Uneven gas flow: Homemade gas manifolds often result in uneven gas flow to each sample position, leading to varied evaporation times between samples in the same batch

3. Fan and Heat-Based Evaporation

Some labs attempt evaporation using hotplates combined with airflow from fans. These setups are highly affordable using such low-cost, accessible materials, but have many potential downsides. It tends to be highly inefficient, slow, and prone to sample loss or contamination.

Best for:

- Labs working with small volatile samples that can evaporate quickly

- Occasional, low-priority solvent removal tasks

- Labs with extremely tight budgets who need to use materials they already have

Limitations:

- Evaporation time can take many hours or even days

- Lack of precision and reproducibility

- Risk of contamination due to open-air solvent exposure

When to Upgrade to a Professional Nitrogen Blowdown System

Homemade evaporation setups may work for extremely low-throughput applications, but a professional nitrogen blowdown system almost always makes sense if you’re evaporating more than a couple of samples at a time or even 10 samples per week.

1. You Need Faster Evaporation

DIY systems struggle with speed, often taking several hours or even days to fully evaporate solvents. A professional nitrogen blowdown system with highly controlled gas flow and the addition of heat can reduce this to minutes, especially for common solvents like acetonitrile, methanol, and acetone.

Find out exactly how fast your samples would evaporate in a nitrogen blowdown evaporator using our evaporation time calculator.

2. You’re Evaporating Multiple Samples at Once

A major drawback of homemade setups is their low throughput. Many are only designed for one or two samples at a time, making them impractical for labs needing to process even small batches. A professional evaporator can process anywhere from 6 to 100+ samples simultaneously, significantly improving lab efficiency.

3. You Want to Reduce Gas Waste

Gas leaks are a common issue in homemade manifold setups, leading to excessive nitrogen waste and increased gas generation costs. A professionally engineered evaporator ensures that nitrogen is delivered efficiently to each sample, reducing operating costs and extending the life of nitrogen tanks or generators.

4. You Need Consistency and Reproducibility

Many DIY solutions suffer from uneven temperature or gas flow between sample positions, leading to uneven evaporation rates and the need for more constant monitoring by a lab tech. Professional systems provide precise control over temperature and nitrogen flow, ensuring consistent, repeatable results across all samples.

5. The Cost of a DIY Setup is Closer to a Professional System Than You Think

Labs that opt for custom-machined sample holders or gas manifolds often spend thousands of dollars on setup and customization—sometimes without realizing that a ready-made nitrogen evaporator costs about the same. Instead of paying for expensive, single-purpose components, investing in a commercial unit provides a turnkey solution with built-in precision and scalability.

Conclusion: Is It Time For You to Upgrade?

DIY evaporation setups, whether it be Schlenk lines, custom manifolds, or hotplate-fan combinations, may work for very small-scale applications, but they introduce long processing times, inefficiencies, and wasted resources. If your lab is evaporating even just 10 samples per week or needs to process multiple samples at once, switching to a professional nitrogen blowdown system can dramatically improve efficiency, cost-effectiveness, and reproducibility.

Instead of spending thousands on custom parts and gas waste, labs can invest in a nitrogen evaporator that delivers fast, precise, and reliable evaporation—making an upgrade the smart and long-term investment.

Speak to our experts today about finding the best sample evaporator for your needs. Under a strict budget? Not to worry! Take a look at our available refurbished evaporators, offered at amazing discounts to keep you under budget.