Nitrogen gas is a staple for many laboratory procedures, mainly within the chemical manufacturing, pharmaceutical, and analytical testing industries. One of the largest uses of nitrogen gas in the laboratory space is sample preparation ahead of Chromatography or Mass Spectrometry (LCMS or GCMS) where a nitrogen blowdown evaporator is used to concentrate liquid samples before analysis. This requires access to a steady, and sometimes high-purity, nitrogen source. Let's take a look at the most common nitrogen generation options that are used in labs today.

Nitrogen Tanks or Cylinders

Nitrogen Tanks or Cylinders

Purchasing nitrogen tanks or cylinders is among the most common nitrogen generation methods, but is surprisingly one of the most inefficient. They're big and bulky, requiring a decent amount of storage space and overall maintenance. You run the risk of running out of nitrogen and having to pause your operation which can negatively impact your test results. Furthermore, they are also not an economical choice with the extra transportation needed to get from the supplier to your facility. Nitrogen tanks are best suited for labs with minimal nitrogen consumption.

→ Discover: How gas cylinders can disrupt gas chromatography sample preparation

→ Discover: Understanding the costs of renting nitrogen gas cylinders in laboratories

Built-in Nitrogen Source

Built-in Nitrogen Source

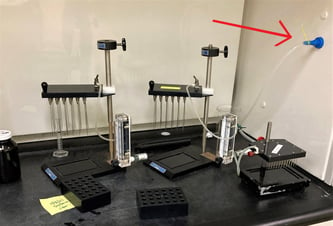

It's typical for large analytical or manufacturing companies to have a nitrogen system that is built directly into the building. This system can supply nitrogen to multiple labs or even to the entire building in some cases. These built-in nitrogen sources are often supplied by an industrial nitrogen generator or a large-scale nitrogen delivery system. Although installing and maintaining a built-in nitrogen system can be quite costly and are only realistic for sizeable labs, they are very convenient for the lab techs who can easily access nitrogen through a spigot in their fume hood.

.png?width=213&height=320&name=NA1955%20(no%20background).png) Membrane Nitrogen Generators

Membrane Nitrogen Generators

Nitrogen generators are an economical and reliable solution, especially for labs who have a high nitrogen consumption rate. Generators are able to separate nitrogen molecules from compressed air, so you will never have to worry about running out of nitrogen gas or switching out tanks. They require minimal maintenance and very little space, so they are often preferred over traditional nitrogen cylinders. There are a few different types of nitrogen generators.

Membrane nitrogen generators work by passing compressed air through a hollow-fiber membrane. Due to its semi-permeable nature, the membrane is able to filter out the smaller oxygen molecules and other impurities in the air, leaving behind nitrogen gas that has a purity range between 95-99%. Read more about how membrane nitrogen generators work and take our generator payback calculator to determine if it will make sense for your lab.

.png?width=255&height=255&name=MISTRAL%20EVO%20Generator%20(side).png) Pressure Swing Adsorption (PSA) Generators

Pressure Swing Adsorption (PSA) Generators

Pressure swing adsorption generators work in a similar way as membrane nitrogen generators. They also require a compressed air source, but instead of being passed through a membrane, the air is passed through two columns of tightly packed material called Carbon Molecular Sieve (CMS). The CMS columns allow nitrogen molecules to pass through, and will adsorb all oxygen and other molecules. Once one sieve becomes completely saturated with oxygen or other materials, the second sieve will depressurize. This reverses the adsorption process, cleaning out the CMS and releasing all the impurities through an outlet. This process will repeat, leaving behind nitrogen gas that has a purity range between 98-99.999%. This makes PSA generators ideal for processes that require ultra high-purity nitrogen. Read more on Pressure Swing Adsorption Technology and watch our video on how pressure swing adsorption works.

→ Discover: Which nitrogen generator technology is right for me?

These four examples are among the most common nitrogen generation methods used in laboratories today. With so many different methods available, it can be difficult to know which one is best for you. Organomation's sales team is here to help - just contact sales@organomation.com or reach out through our live chat during normal business hours.

For more information on nitrogen generators, check out this comprehensive guide: Nitrogen Generators: Everything You Need to Know