Effective nitrogen blowdown evaporation balances gas flow and heat to remove solvent quickly without degrading delicate samples. Here are some tips to optimize your blowdown evaporation.

Rule #1: Select the correct flow rate and needle gauge for your tube size

Effective blowdown evaporation starts with proper gas flow. Optimal flow rate depends on size of the gas delivery needles used. Small samples can be efficiently concentrated with 19 gauge needles, while wider tubes benefit from the higher flow allowed by larger needles.

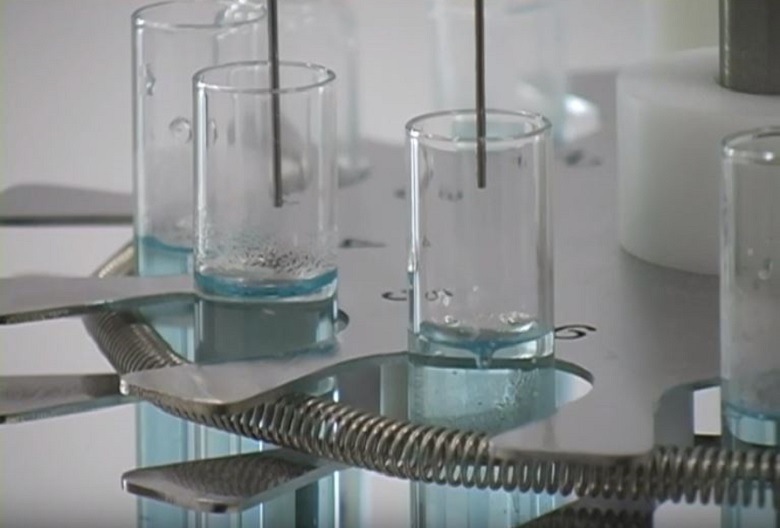

Whichever needles you use, at a proper flow rate, the gas stream should be strong enough to create a visible dimple in the surface of the sample while still minimizing splashing. This ensures that the gas stream disrupts and removes the solvent vapor layer above the sample, allowing more solvent to evaporate.

Rule #2: Apply heat when necessary

A bath temperature of 2-3 °C below the boiling point of the solvent is ideal to promote efficient evaporation without subjecting the sample to the harsh conditions of boiling. For heat-sensitive samples, a bath temperature of around 30 °C to 40 °C will help to combat the cooling effect of evaporation.

Rule #3: Use dry gas for blowdown

There are several gas source options for blowdown evaporation, including nitrogen cylinders, lab air or nitrogen, or a nitrogen generator. Nitrogen purity requirements are determined by the chemist—even clean air can work for evaporation. The most important consideration is that the gas be dry. Most nitrogen gas typically has a low moisture content already, but compressed air needs to be dried to promote efficient evaporation.

Rule #4: Keep needles close to the surface of the sample

Remember, evaporation is fastest when the gas stream successfully disrupts the vapor layer above the sample. The closer the gas delivery needles are to the surface of the sample, the less gas will be required for effective evaporation. To conserve nitrogen, always keep needles close to the sample’s surface.

Rule #5: Clean the needles if any splashing occurs

Cleaning needles after use, especially if any solvent has splashed on them, is the best way to prevent contamination between samples. Regular cleaning will also greatly prolong the life of the needles. For a lower maintenance solution, try using disposable glass pipettes instead for nitrogen delivery.

Nitrogen blowdown evaporation explained:

About Organomation

Since 1959, Organomation has been a global leader in laboratory evaporation solutions. Organomation’s popular N-EVAP and MULTIVAP evaporators are used in laboratories worldwide.

Contact sales@organomation.com with any questions!