Customer Success Story Highlighting Valcor Engineering’s Use of the S-EVAP+ Vacuum Evaporator in a Cleanroom.

"The ability to evaporate multiple samples in parallel provides a bigger benefit than traditional rotary evaporators and helps solve a major bottleneck in the processing of our products." - Mateo Nieto, Jr. Process Engineer at Valcor

Company Overview

Founded in 1951 and headquartered in Springfield, New Jersey, Valcor Engineering Corporation is a global leader in designing and manufacturing precision fluid-control components and systems for aerospace, nuclear, industrial, and scientific applications. From satellites and launch vehicles to advanced research facilities, Valcor products are trusted in mission-critical applications where reliability and performance are paramount.

Challenge: High-Throughput Evaporation in a Cleanroom

Valcor’s cleanroom laboratories are tasked with capturing and analyzing non-volatile residue from hardware used in demanding aerospace environments. After the stainless steel hardware is flushed with high-purity solvents, technicians must fully evaporate the solvent to accurately measure any remaining residue.

Historically, Valcor relied on rotary evaporators for this critical evaporation step. While effective for individual samples, rotary evaporators presented two major bottlenecks:

1. Limited Capacity: Each rotary unit processes just one sample at a time. Running batches samples meant either operating multiple units (taking up valuable benchtop space and requiring additional resources) or performing back-to-back runs (a truly time-consuming process).

2. Labor-Intensive Workflow: A technician must monitor the rotary unit and spend about five minutes swapping each flask once a sample finishes. For a five-sample batch, that adds at least 25 minutes of hands-on time, even before considering the evaporation itself.

These factors created extended cycle times for Valcor, and tied up their valuable cleanroom space and personnel.

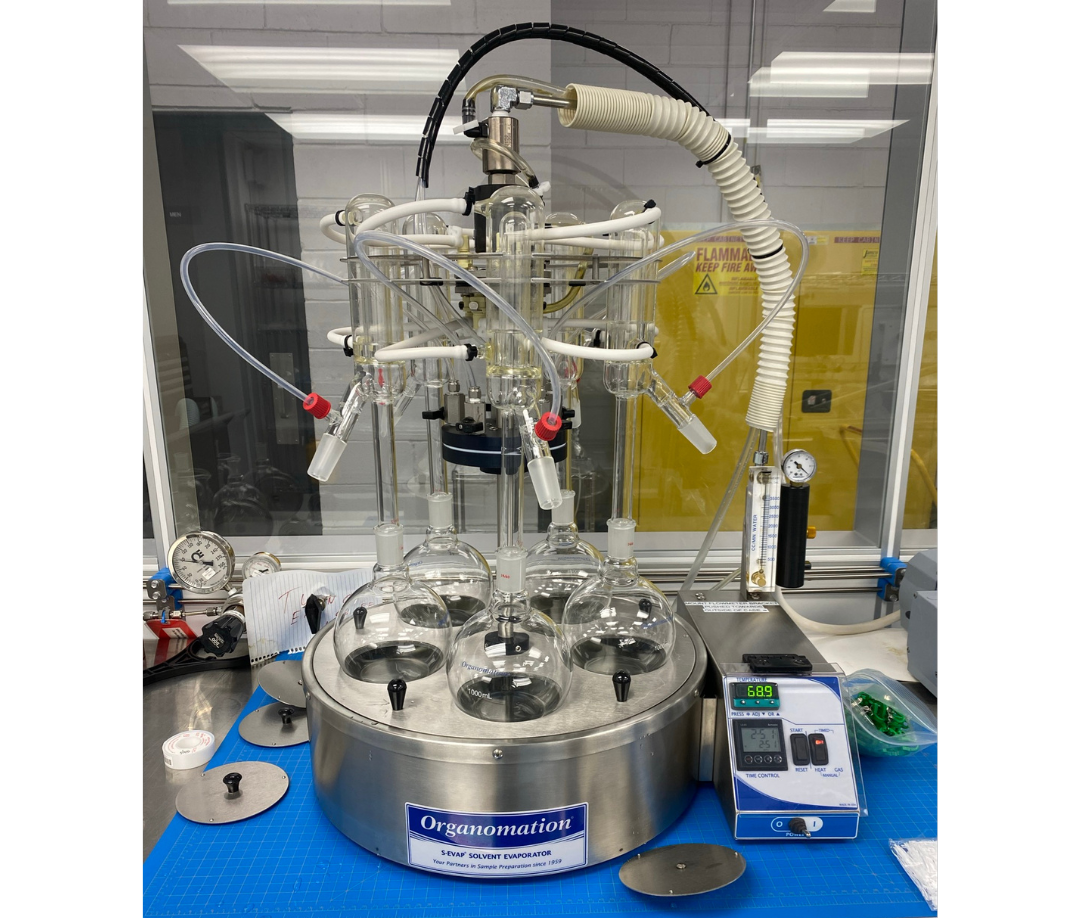

Solution: Organomation S-EVAP+ Vacuum Evaporator

To streamline operations, Valcor adopted the Organomation S-EVAP+, a high-capacity vacuum evaporator built for parallel sample processing. Installed directly in their cleanroom, the S-EVAP+ allows five 100 mL samples to evaporate simultaneously under carefully controlled temperature and vacuum conditions.

Key operating parameters include:

- Vacuum: 27 inHG

- Bath Temperature: 95 °C (chiller coolant at 13 °C)

- Solvent: 99.9% Isopropyl Alcohol

- Sample size: 100 mL evaporated to ~0 mL

This single instrument eliminated the need for multiple rotary units and consolidated Valcor’s evaporation steps into one efficient system.

Performance: Quantifiable Time and Labor Savings

Valcor’s testing shows that 100 mL isopropyl alcohol samples reach dryness in about 14 minutes on the S-EVAP+ (using the parameters above) compared to roughly 6 minutes on a single rotary evaporator. Although a rotary unit is quicker for one sample, the S-EVAP+ excels with higher throughput, accommodating up to five samples at once. Its larger capacity and reduced need for technician oversight make it the faster overall solution for multi-sample evaporation.

| Samples (IPA) | Rotary Evaporator* | S-EVAP+ Evaporator (Parallel)** | Total Time Saved |

|---|---|---|---|

| 5 × 100 mL | 30 min evaporation + 25 min flask changes = 55 min |

14 min evaporation (1 batch) + 5 min flask setup = 19 min |

36 minutes |

| 10 × 100 mL | 60 min evaporation + 50 min flask changes = 110 min |

28 min evaporation (2 batches) + 10 min flask setup = 38 min |

72 minutes |

| 15 x 100 mL | 90 min evaporation + 75 min flask changes = 165 min |

42 min evaporation (3 batches) + 15 min flask setup = 57 min |

108 minutes |

* Assumes 6 minutes evaporation and ~5 minutes of technician time to switch each flask.

** Assumes 14 minutes evaporation per batch of 5 samples and ~5 minutes of technician time to load all flasks.

By running five samples in a single batch, the S-EVAP+ cuts total evaporation time to nearly one-third and frees technicians from repetitive flask changes, enabling them to focus on other important tasks.

Advantages Over Rotary Evaporators

Beyond sheer speed, Valcor identified several key benefits:-1.jpg?width=268&height=357&name=Image%20(1)-1.jpg)

1. Higher Capacity in Less Space: One compact unit replaces multiple rotary evaporators, conserving valuable cleanroom real estate.

2. Lower Resource Demands: A single chiller and vacuum pump support all five samples, reducing utility and maintenance costs.

3. Labor Efficiency: Parallel evaporation eliminates constant monitoring and flask changes, dramatically reducing hands-on time.

4. Cleanroom Compatibility: The bath’s corrosion-resistant construction helps maintain a debris-free environment critical for aerospace applications.

Valcor's Jr. Process Engineer, Mateo Nieto, said:

“The biggest benefit is that the S-EVAP+ system covers less workspace for what it would take rotary evaporators to do the same work while being more efficient and utilizing less resources (chillers, vacuums). The ability to evaporate multiple samples in parallel provides a bigger benefit than traditional rotary evaporators and helps solve a major bottleneck in the processing of our products. We’ve also noticed that the material of the bath wall does not produce the same corrosion that we’ve come across with other evaporators, limiting the amount of debris found inside of our cleanroom environments.

The S-EVAP+ seems promising in its ability to run multiple samples at once while improving efficiency and lowering cycle times in our testing procedures."

Outcome

With the Organomation S-EVAP+, Valcor Engineering now completes multi-sample evaporation runs in roughly one-third of the time required by their rotary setup, while also freeing technicians from more the monotenous task of manual flask handling and swapping. The result is faster throughput, reduced labor costs, and a cleaner, more efficient operation—all essential to Valcor’s mission of delivering precision aerospace components on schedule. Learn more about Valcor here: www.valcor.com

Not sure if the S-EVAP+ is the best choice for your lab? Use our S-EVAP+ or rotary evaporation tool below to find out!