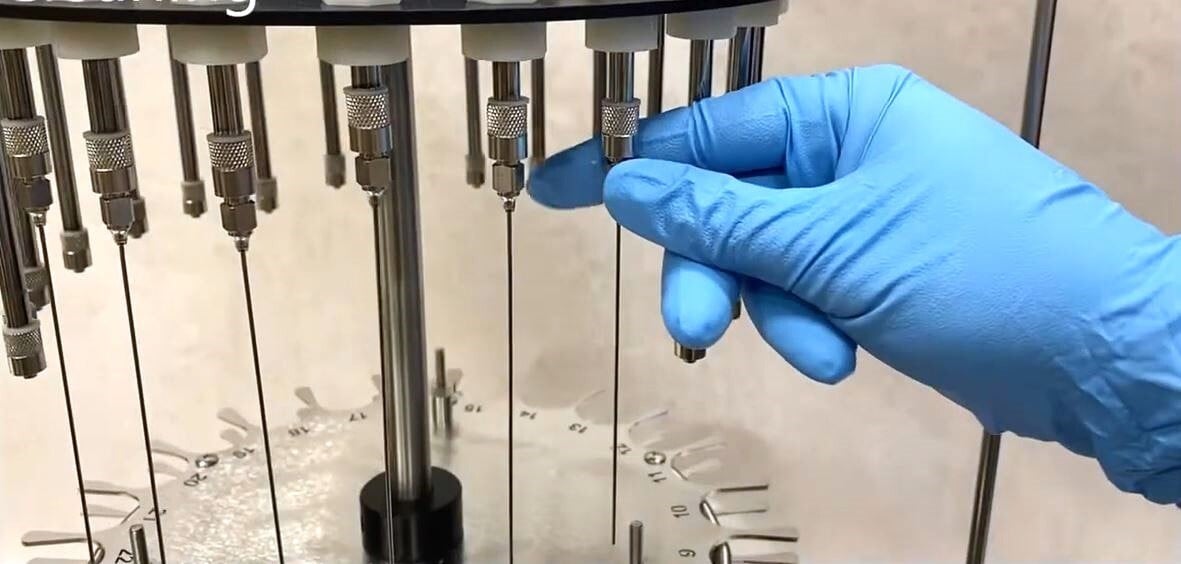

Organomation’s standard model evaporators come with evaporation needles made from 304 stainless steel. While these needles are compatible with many organic solvents commonly used for extractions, some corrosion can occur. Since the evaporation needles are in closest proximity to the solvents being evaporated, they take the brunt of the contact with solvent vapor and are often the first part to corrode in the instance of solvent compatibility issues. It is not unusual for solvent droplets to form on the tips of the needles during evaporation.

Needles are meant to be semi-consumable, and replacement is recommended every 1-2 years to minimize corrosion, blockage, and physical damage such as bends. After two years, corrosion to the needles should be minimal (i.e. surface rust) if observed at all. If the needles on an Organomation evaporator are corroding significantly faster than this, consider washing the needles more frequently or upgrading to Teflon-coated needles for increased solvent resistance.

We would recommend pairing Teflon-coated needles with a standard evaporator in the following cases:

1. For use with weak acids and bases, for instance acetic acid, formic acid, or ammonium hydroxide. While a fully acid-resistant model will exhibit less corrosion over its lifespan, a standard model with acid-resistant needles provides a cost-effective alternative since the bulk of the expected corrosion will be to the needles (the needles take the brunt of the solvent vapor). Expect to see superficial corrosion over time to stainless steel, anodized aluminum, chrome-plated, and acetal parts.

a. Note: For infrequent use with weak acids / bases, or for use with only low concentrations of weak acids / bases, a standard model with stainless steel needles is typically fine.

b. Note #2: For strong acids such as HCl or TFA, a fully acid-resistant model is strongly recommended. These acids will often corrode more than just the needles, and frequent use in a standard model evaporator can quickly lead to major repair issues.

2. For use with the following corrosive organic solvents:

a. Diethyl ether, ethyl acetate, isopropanol, methylene chloride (DCM), pentane, pyridine.

b. Similarly to use with weak acids, a fully acid-resistant model will provide the best protection against these solvents. However, as the needles will take the brunt of the corrosion, a standard model with Teflon-coated needles is a viable alternative with only a slight decrease in expected lifespan.

3. To mitigate corrosion, Organomation recommends that needles be rinsed after each use. Teflon-coated needles can help to extend the lifespan of the needles in installations where rinsing the needles after each use is not feasible.

a. Read more: Organomation's full needle cleaning instructions

Since Organomation’s evaporation needles are designed to be replaceable, Teflon-coated needles can be added to an evaporator after the fact if issues with needle corrosion are observed.

To determine if you should switch to using acid resistant needles, please refer to the chemical compatibility chart below. For any questions or concerns, please reach out to our team at sales@organomation.com.

Visit our online store to purchase a set of Teflon-coated needles.

Chemical Compatibility Chart

| Solvent | Standard needles (NA0603) | Teflon-coated needles (NA0603-T) |

| Acetic acid 20% | B | A |

| Acetic acid 80% | NR | A |

| Acetone | A | A |

| Acetonitrile | A | A |

| Ammonium hydroxide** | B | A |

| Chloroform | A | A |

| Diethyl Ether | B | A |

| Ethanol | A | A |

| Ethyl acetate | B | A |

| Formic acid | C | A |

| Heptane | A | A |

| Hexane | A | A |

| Hydrochloric acid* | NR | A*** |

| Isooctane | A | A |

| Isopropanol | B | A |

| Methanol | A | A |

| Methylene chloride (DCM) | B | A |

| MTBE | A | A |

| n-butanol | A | A |

| Pentane | C | A |

| Petroleum ether | A | A |

| Pyridine | B | A |

| Trifluoroacetic acid (TFA)* | NR | A |

| Toluene | A | A |

| Water | A | A |

A: Minimal corrosion expected

B: Slight corrosion possible if needles are not rinsed frequently

C: Some corrosion expected with repeated use

NR: Not recommended

*Full acid-resistant model strongly recommended

**<2% methanolic ammonium hydroxide, as called for in EPA methods 533 and 1633 for the analysis of PFAS in water samples, can be used with standard stainless steel needles without issue. Teflon-coated needles are not recommended for this application due to the possibility of PFAS contamination.

***Some corrosion over time is expected when using concentrated hydrochloric acid, for instance 6N or 3N HCl in n-butanol.

References: