Product Information, Sample Concentration Options

/ Organomation

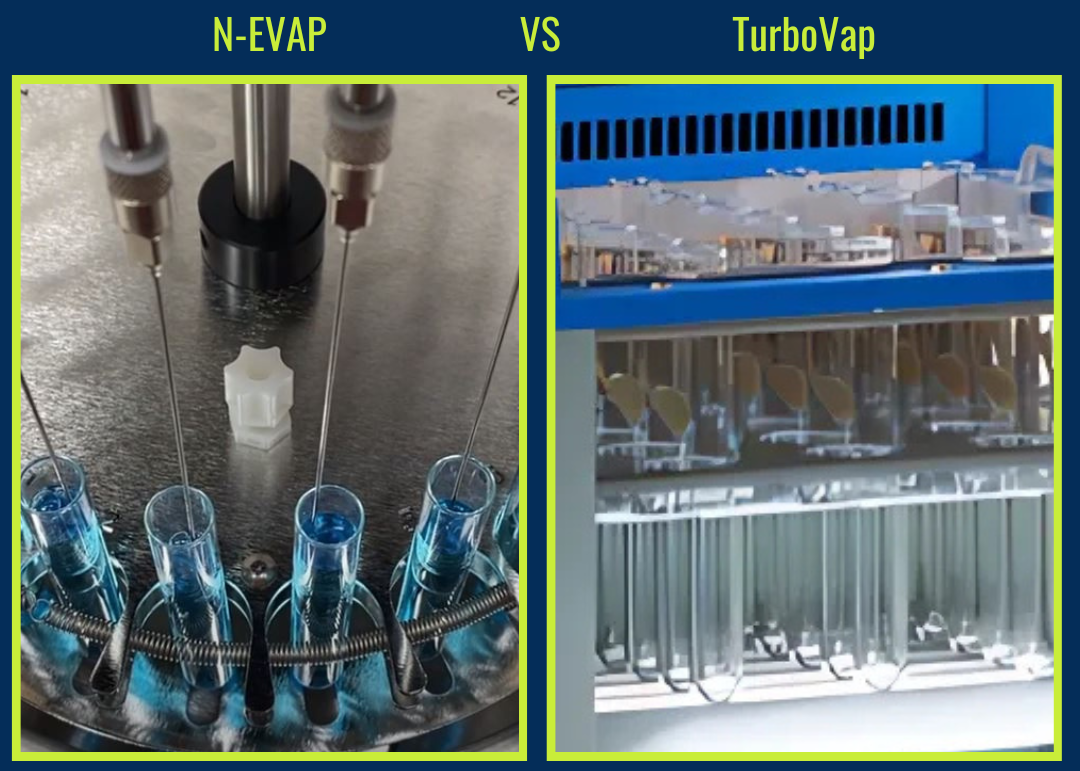

The choice between Organomation's N-EVAP and the Biotage TurboVap can significantly impact both your workflow and overall efficiency. Each system has been engineered with unique features that cater to different needs, making the selection process crucial depending on your specific requirements. Whether it's sample capacity, flexibility, gas flow control, or operational efficiency, understanding the strengths of each system is essential for making an informed decision.

This blog will explore a detailed comparison of the N-EVAP and TurboVap, highlighting their key features and differences. We'll look at how each system performs in various aspects, from handling multiple sample sizes and controlling gas flow to their nitrogen consumption and temperature ranges. By the end of this analysis, you'll gain valuable insights to help you choose the evaporation system that best fits your laboratory's needs and operational goals.

Would a batch evaporator be a better fit for you?

Sample Capacity and Flexibility

The N-EVAP can hold 6, 12, 24, 34, or 45 samples, and multiple tube sizes at once. It features independent gas flow to each sample. If you will be working with a variety of different tube types or sample volumes, which often occurs when the instrument will be shared across multiple teams, the N-EVAP will be better suited for your needs. The TurboVap can hold either 24 or 48 samples, and only one tube size at a time. It features independent gas flow to each row, as opposed to each sample.

The N-EVAP has a spring style sample holder that allows it to hold any tubes between 10-30 mm OD at the same time, without modification. The N-EVAP’s individual valve tube assemblies also allow you to adjust the needle height and gas flow to each sample separately for optimal control of various sample types. The TurboVap’s rack only allows one tube size to be held at once. If you’ll be working with large batches of identical samples, a MICROVAP, MULTIVAP, or TurboVap will be the better option.

Although the individual valve tube assemblies of the N-EVAP offers the most amount of user control, they can make uniform batch evaporation tricky. The singular manifold on the TurboVap allows for more even and controlled evaporation when the goal is for all your samples to be complete at the same time.

Price

For labs that have a limited budget, such as start-ups or academic labs who are restricted by grant funding, the N-EVAP provides a much more affordable option than the TurboVap. Even the highest capacity N-EVAP with additional features is less than the base model TurboVap. The simplicity of Organomation’s units allows for an inexpensive unit with minimal maintenance and repair costs.

Be sure to download the PDF version of the Organomation N-EVAP vs the Biotage TurboVap to see actual pricing.

Digital Features and Automation

Unlike the N-EVAP which has a button-interfaced control box, the TurboVap includes a digital touch

screen where you can control the heat and gas flow. The digital system allows you to save preferences

and methods in the system for future use. Although entirely preference-based, the touch screen feature

can provide a more modern approach to the evaporation process.

For labs that require a more hands-off evaporation experience, the TurboVap will be the better solution. The TurboVap LV allows the gas flow to slowly increase throughout the evaporation cycle eliminating manual adjustments, and also includes an alarm that goes off once your samples have reached a specific volume. Conversely, the higher capacity N-EVAPs include a timer function that can shut the heat and gas flow off after a specified amount of time. Although it is not based on solvent volume, the timer can be just as useful once you’re familiar with your evaporation rates.

Nitrogen Consumption

The N-EVAP requires much less nitrogen flow than the TurboVap, making it the better option for labs who are looking to conserve their gas consumption. For comparison, the 24 position TurboVap requires 120 L/min of nitrogen while the 24 position N-EVAP only requires 8 L/min. Whether you’re using nitrogen tanks or producing your own nitrogen with a generator, the minimal gas usage of the N-EVAP provides a much more affordable and economical option.

Temperature Range

When working with solvents that have a boiling point above 90 °C, such as heptane, pyridine, or toluene, the N-EVAP will be a more suitable option as it can promote faster evaporation rates. The dry bath N-EVAPs utilize either aluminum or glass beads which allow the bath temperature to reach up to 130 °C. In comparison, the TurboVap only reaches 90°C.

Safety with Corrosive Solvents

Although both units have an acid resistant version to prevent corrosion, the N-EVAP is rated for a higher concentration of strong acids or bases, such as hydrochloric acid, formic acid, or tetrahydrofuran. For comparison, the N-EVAP is rated for concentrations of up to 3M of HCl while the TurboVap is only rated for concentrations of up to 0.1M HCl. If you’ll be working with these types of corrosive solvents, the PTFE-coated N-EVAP will provide a longer-lasting solution.

Tube Visibility

If it’s important for you to keep an eye on your test tubes throughout the evaporation process, the TurboVap would be preferred. The TurboVap’s water bath has a glass casing that allows your samples to remain visible as the solvent level goes down, which can be valuable when drying to a specific end-point or to complete dryness. The N-EVAP has an aluminum water bath, which allows you to view your samples from the top. You can lift the samples out of the bath for

quick visibility, but this does require you to remove them from the heat source, possibly slowing down the evaporation process.

Placement

The TurboVap models have the option to either be used within a fume hood, or to be connected to a ventilation system using an exhaust outlet at the back of the unit. If your lab has limited fume hood space, or even no fume hood at all, the TurboVap allows you to use it on just a regular benchtop workspace. The general recommendation is to always use the N-EVAP within a fume hood, however a portable fume extractor can also be used in instances where that’s not possible.

Conclusion

In the comparison between Organomation's N-EVAP and the Biotage TurboVap, it’s evident that both systems bring unique strengths to the table, tailored to different laboratory needs.

The N-EVAP offers more sample capacity flexibility, allowing it to adapt to varying batch sizes more effectively. Additionally, the N-EVAP’s capability to handle multiple tube sizes simultaneously offers greater versatility for labs using various tube sizes. The TurboVap is better suited to batch evaporation, and offers more clear tube visibility while the unit is in use.

The N-EVAP is notably more efficient in nitrogen consumption, using just 15 L/min compared to the TurboVap’s 160 L/min. This significant difference not only impacts operational costs but also contributes to a more sustainable lab environment. The acid resistant models are also less prone to solvent corrosion compared to the TurboVap.

The TurboVap features digital and automated controls that the N-EVAP does not, and it can also be used outside of a fume hood.

The N-EVAP offers a higher level of flexibility, efficiency, and broader temperature range, making it a strong choice for labs that require versatile and cost-effective solutions. While the TurboVap is a reliable option, particularly in settings where space is a premium and specific configurations are needed, the N-EVAP’s features may provide enhanced value at a lower price for labs seeking to maximize sample throughput and operational efficiency.