The determination of total organic carbon (TOC) and dissolved organic carbon (DOC) in water samples requires precise removal of inorganic carbon (IC) to avoid analytical interference. EPA Method 415.3 outlines a robust protocol for this process, employing specialized equipment such as the N-EVAP Nitrogen Evaporator System as a critical sparging apparatus.

This article explores the technical adaptation of the N-EVAP for IC removal, its integration into the method’s workflow, and its significance in ensuring accurate organic carbon measurements in source and drinking waters.

Role of Sparging in Organic Carbon Analysis

Inorganic Carbon Interference

Inorganic carbon, primarily from carbonates and dissolved CO₂, contributes to erroneous TOC/DOC readings if not fully eliminated. Method 415.3 mandates IC removal prior to analysis through acidification followed by sparging—a process where inert gas (e.g., nitrogen) uses finely dispersed bubbles through the sample, volatilizing IC as CO₂ gas.

Sparging Efficiency Requirements

Effective sparging must reduce IC concentrations to levels indistinguishable from background organic carbon contamination (≤0.35 mg/L OC). Incomplete removal introduces positive or negative biases, depending on the TOC instrument’s calculation method (e.g., TC = TOC +TIC vs. TOC = TC – TIC).

Adaptation of Nitrogen Evaporator for Sparging

Original Design vs. Method Application

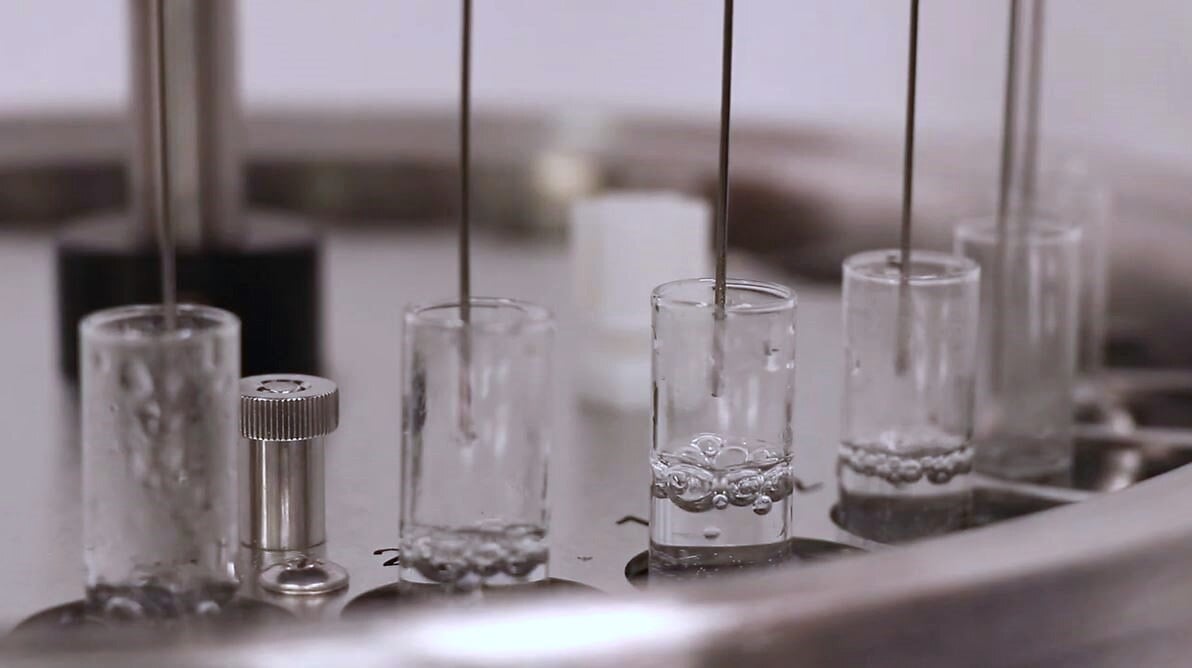

The N-EVAP is traditionally used for evaporating solvents under a stream of nitrogen. However, Method 415.3 repurposes it by submerging its stainless-steel needles into dilute acidified 40 mL injectable vials. Key operational parameters include:

- Gas Flow Rate: 100–200 mL/min of ultra-high-purity (UHP) nitrogen.

- Sparging Duration: 20 minutes per vial

- Acidification: Samples are preserved using H₃PO₄, HCl, or H₂SO₄ to convert carbonates to CO₂.

Technical Workflow

1. Sample Preparation: After acidification, samples are transferred to 40 mL injection vials, avoiding particulates or floating matter.

2. Sparging Setup: The N-EVAP needles are submerged, and nitrogen gas is delivered at controlled rates.

3. IC Removal Validation: Post-sparging, samples must pass the IC removal efficiency test (Section 9.2.4), where treated IC-TEST solutions (100 mg/L IC) yield ≤0.35 mg/L OC.

Quality Assurance and Challenges

Cleaning and Contamination Control

The N-EVAP apparatus requires rigorous cleaning to prevent cross-contamination:

- Pre-/Post-Use Protocol: Needles are rinsed with dilute acid (e.g., 40 µL H₃PO₄ in 40 mL LRW) and flushed with nitrogen.

Method-Specific Adjustments

- High IC Matrices: Samples with IC >100 mg/L (e.g., Saint Leon Well Water) demand extended sparging or higher flow rates to meet detection limits.

The N-EVAP’s adaptation as a sparging device in EPA Method 415.3 underscores its versatility in environmental analysis. By ensuring efficient IC removal, it supports regulatory compliance and high-quality data generation for TOC, DOC, and SUVA metrics. Future advancements may integrate automated sparging systems, but the N-EVAP’s manual operation remains indispensable for laboratories prioritizing flexibility and cost-effectiveness.

Learn how a proteomics lab utilizes a nitrogen evaporator to purge O2 from their solution.