Why Laboratories Need to Reconsider Their Gas Supply Strategy

When discussing the transition to nitrogen generators, most industry conversations focus on replacing traditional compressed nitrogen gas cylinders. However, this narrative overlooks a significant segment of laboratory operations that rely on liquid nitrogen tanks as their primary source of nitrogen gas. While liquid nitrogen systems may appear more sophisticated and cost-effective than high-pressure cylinders, they harbor substantial inefficiencies that can dramatically impact laboratory operations, safety, and economics. This article examines the often-overlooked drawbacks of liquid nitrogen tank systems and explores why laboratories should consider on-site nitrogen generation as a superior alternative to both cylinders and liquid nitrogen storage.

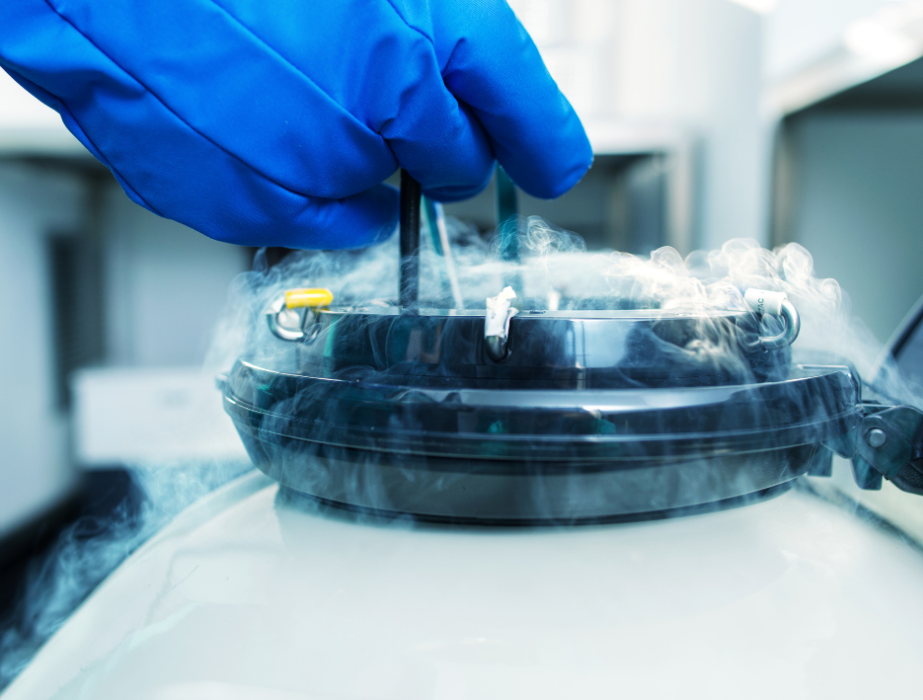

Major Inefficiencies of Liquid Nitrogen Tank Systems

Continuous Evaporation Losses

The most significant inefficiency in liquid nitrogen tank systems stems from continuous evaporation losses that occur regardless of actual nitrogen consumption. Research conducted on cryostorage tank performance demonstrates that even properly functioning tanks with intact vacuum insulation experience ongoing evaporation rates that can exceed one liter per day. This represents a baseline loss that occurs simply due to heat transfer through the tank's insulation system.

Environmental laboratories like Belmont Labs documented that 25% of each liquid nitrogen cylinder was routinely lost to venting procedures designed to prevent dangerous pressure buildup. This substantial loss occurs as a necessary safety measure, not due to operational inefficiency or equipment malfunction. The venting process is mandatory to prevent explosive pressure buildup that could result in catastrophic tank failure.

Vacuum System Failures and Catastrophic Losses

Liquid nitrogen tanks rely on vacuum insulation systems to minimize heat transfer and reduce evaporation rates. When these vacuum systems fail, the consequences are dramatic and immediate. The research from the Journal of Assisted Reproduction and Genetics cited above shows that tanks with compromised vacuum systems experience evaporation rates that increase from less than one liter per day to over 40 liters per day within the first six hours of vacuum failure.

The study of vacuum-compromised tanks revealed that smaller capacity systems (30-47 liters) could be completely depleted within 18-35 hours following vacuum failure. External indicators of vacuum loss include dramatic vapor production, frost formation, and audible air movement, but these signs may not be immediately apparent to laboratory personnel.

Pressure Relief and Safety Venting Waste

The mandatory safety systems in liquid nitrogen tanks create ongoing waste streams that laboratories must accept as operational costs. Pressure relief devices automatically discharge nitrogen gas when predetermined pressure thresholds are exceeded, regardless of whether the laboratory requires the gas at that moment. This safety venting is non-negotiable and represents pure waste from an operational perspective.

University safety protocols document multiple scenarios where complete tank venting is required, including uncontrollable leaks, valve failures, and maintenance procedures. The University of Pennsylvania reported incidents where liquid dispensing valve failures resulted in violent releases of liquid nitrogen, requiring complete evacuation and tank venting. These safety-mandated losses can result in the complete loss of remaining tank contents.

Temperature and Environmental Dependencies

Liquid nitrogen tank efficiency is heavily dependent on environmental conditions, creating variable and unpredictable operating costs. Hot and humid weather conditions accelerate evaporation rates and increase the frequency of pressure relief venting. Ice formation on relief valves during hot weather can cause valves to remain open, leading to continuous gas loss until manually corrected.

The pressure-building systems that convert liquid to gas are particularly sensitive to ambient temperature variations. During hot weather, the external coils that provide heat for vaporization become more efficient, potentially leading to excessive pressure buildup and increased venting frequency. Conversely, cold weather can reduce conversion efficiency, requiring longer pressure-building cycles and potentially inadequate gas supply during peak demand periods.

Operational and Economic Impacts

Supply Chain Vulnerabilities

Liquid nitrogen systems create significant supply chain dependencies that can disrupt laboratory operations. Simply put, supply disruptions can halt research activities and compromise time-sensitive experiments.

The transportation and delivery requirements for liquid nitrogen create additional vulnerabilities. Specialized cryogenic transport vehicles are required, and delivery schedules may not align with laboratory demand patterns. Unlike on-site generation systems, liquid nitrogen supplies cannot be increased on-demand, potentially leading to rationing during supply shortages or unexpected demand spikes.

Maintenance and Safety Compliance Costs

Liquid nitrogen tanks require specialized maintenance and regular inspection protocols that add to operational costs. Tanks must be inspected upon delivery and undergo comprehensive integrity evaluations. The complexity of pressure-building systems, relief valves, and vacuum insulation creates multiple potential failure points requiring professional servicing.

Safety compliance requirements include specialized handling equipment, personal protective equipment, and environmental monitoring systems. Laboratories must maintain oxygen monitoring equipment to detect dangerous oxygen displacement, and personnel require specialized training in cryogenic handling procedures.

Space and Infrastructure Requirements

Liquid nitrogen tank systems require significant laboratory space and specialized infrastructure. Large tanks can weigh over 700 pounds when full, requiring reinforced flooring and specialized moving equipment. The tanks must be positioned in well-ventilated areas to prevent oxygen displacement hazards, potentially limiting placement options within laboratory facilities.

The infrastructure requirements extend beyond the tanks themselves to include specialized gas distribution systems, pressure regulators, and safety equipment. Unlike compact nitrogen generators that can fit on benchtops or under laboratory counters, liquid nitrogen systems require dedicated floor space and clearance for delivery access.

Comparison With On-Site Nitrogen Generation

Elimination of Waste Streams

On-site nitrogen generators eliminate the fundamental waste streams inherent in liquid nitrogen systems. Generators produce nitrogen on-demand, eliminating the continuous evaporation losses that occur in storage systems. The Belmont Labs achieved annual savings of approximately $7,800 primarily by eliminating the 25% venting losses associated with their previous liquid nitrogen system.

Nitrogen generators operate without the pressure relief requirements that create mandatory waste in liquid nitrogen systems. The N2 membrane and pressure swing adsorption technologies used in generators separate nitrogen from compressed air without creating the pressure buildup issues that necessitate safety venting. This fundamental difference in operating principles eliminates the largest source of waste in liquid nitrogen systems.

Operational Reliability and Control

On-site generation provides laboratories with complete control over their nitrogen supply, eliminating the supply chain vulnerabilities associated with liquid nitrogen delivery. Generators operate continuously, providing nitrogen as needed without the feast-or-famine cycles created by periodic tank deliveries. The systems can adjust purity levels to match specific application requirements, providing operational flexibility unavailable with pre-supplied liquid nitrogen.

The Organomation NITRO-GEN+ N2 generator can provide up to 35 standard liters per minute of 98% pure nitrogen with user-controlled output pressure. This on-demand capability eliminates the need to maintain large inventories of liquid nitrogen and reduces the risk of running out of gas during critical operations.

Environmental and Economic Benefits

Nitrogen generators significantly reduce the environmental impact associated with liquid nitrogen production and transportation. The cryogenic production of liquid nitrogen requires substantial energy input for liquefaction and specialized transportation in insulated tanker trucks. On-site generation eliminates these transportation requirements and the associated carbon footprint.

The economic analysis from Belmont Labs demonstrated a payback period of less than two years for their nitrogen generator investment. The elimination of delivery charges, tank rental fees, and waste losses created ongoing operational savings that quickly offset the initial equipment investment. Additionally, generators eliminate the hidden costs associated with maintaining liquid nitrogen inventories and managing delivery schedules.

Save Money and Bolster Reliability Through On-Demand Nitrogen Generation

The inefficiencies of liquid nitrogen tank systems in laboratory settings extend far beyond simple operational inconveniences. The mandatory 25% waste through safety venting, continuous evaporation losses, vulnerability to catastrophic vacuum failures, and complex supply chain dependencies create substantial hidden costs that many laboratories fail to fully account for in their nitrogen supply strategies. The conversion process from liquid to gas, while thermodynamically sound, introduces multiple inefficiency points that are inherent to the technology rather than correctable through improved operations.

The case study evidence from facilities like Belmont Labs demonstrates that transitioning from liquid nitrogen systems to on-site nitrogen generation can provide rapid return on investment while eliminating the fundamental waste streams that plague liquid nitrogen operations. As laboratories increasingly focus on operational efficiency and environmental sustainability, the hidden inefficiencies of liquid nitrogen systems make a compelling case for reconsidering nitrogen supply strategies beyond the traditional cylinder-versus-generator comparison.

The future of laboratory nitrogen supply lies in systems that eliminate waste rather than managing it, provide operational control rather than supply chain dependency, and offer predictable costs rather than variable losses. On-site nitrogen generation represents this evolution, addressing the fundamental inefficiencies that make liquid nitrogen tanks an increasingly obsolete technology for modern laboratory operations.

Thinking about switching to an on-site nitrogen generator? Calculate how much you could save by making the switch: